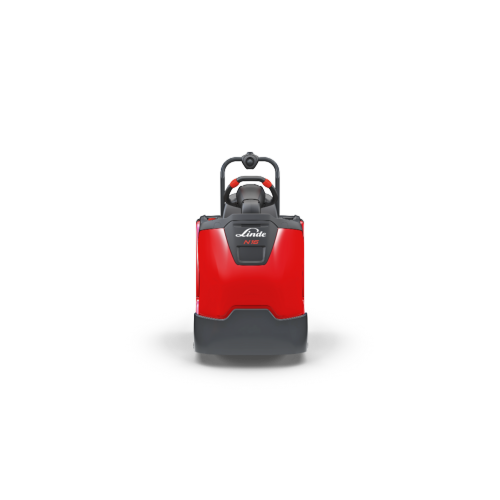

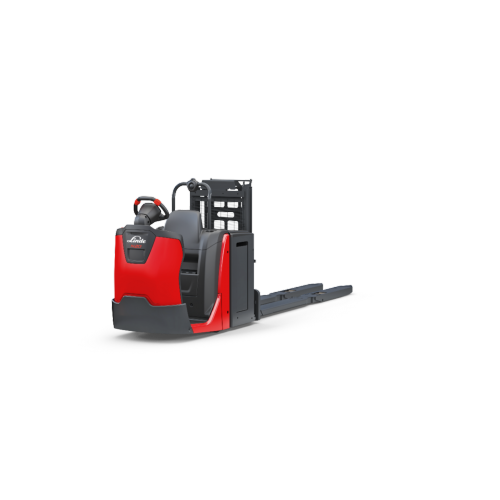

Electric Pallet Stacker with Ergonomic Platform

The L14 P electric pallet stacker from Linde Material Handling ensures precise stacking and transport, as well as a safe and efficient material flow. The truck can carry loads of up to 1,400 kg and reach a maximum speed of 6 km/h. Thanks to the fold-out platform, operators can cover short and medium distances in warehouses without any difficulties. The platform's special suspension eliminates any vibrations and shocks when on the move and the non-slip rubber mat ensures operators maintain a secure footing. The Linde OptiLift® control system is quiet and energy saving, and enables operators to handle loads with absolute precision. Thanks to this intuitive system, operators can control all driving and lifting maneuvers with just one finger, while maintaining a good view through the mast. A creep speed button on the ergonomic tiller head also reduces the speed to 1.5 km/h in pedestrian truck mode, making maneuvering in tight warehouse environments even safer.