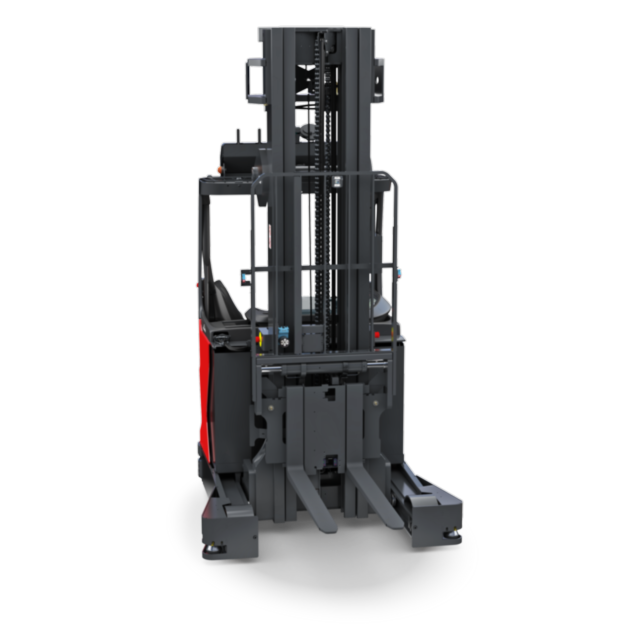

Efficient and precise handling at high lifting heights

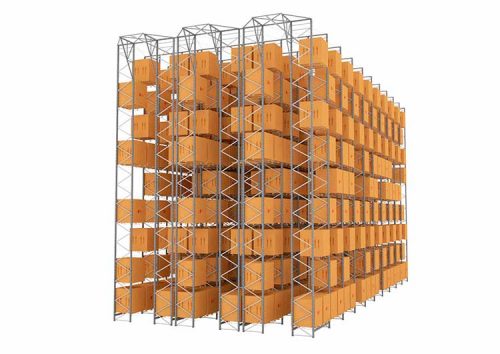

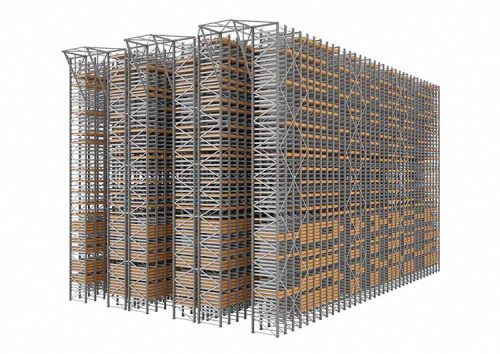

The autonomous R-MATIC reach truck transports and stores and retrieves goods up to 1600 kg at heights of up to more than eleven meters. The range of masts means that it is especially suited to handling at medium to high lifting heights and to supplying workstations, as well as being suitable for warehouses or material transportation. The R-MATIC uses its innovative 3D camera to detect the storage location in the rack and the pallet openings. It can store and retrieve its load precisely by adjusting the prongs. The truck’s geonavigation does not require any additional infrastructure and it interacts safely and efficiently with individuals, non-automated trucks, or conveyor belts and packing stations. Dual Mode means that the R-MATIC can also be controlled manually.