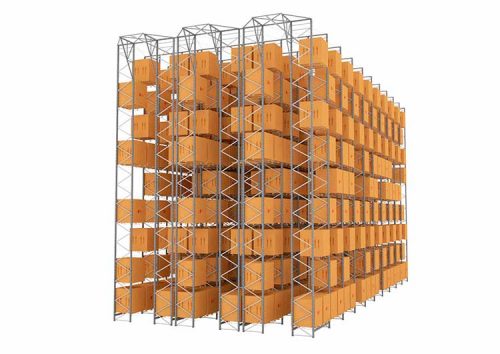

This storage system is ideal for warehouses where stock turnover control and space saving are critical. The compact structure uses slightly inclined roller beds on each level to allow unit loads to be moved more easily. AR Racking offers two types of live pallet racks:

Gravity Fed Used for the FIFO system (First In, First Out), in which the loading area is at the opposite end to the unloading area, and the goods move along this space thanks to the inclined roller bed system.

Push-back. Mostly used for the LIFO system (Last In, First Out); this has only one loading and unloading point: the goods are stored by pushing the previous ones towards the back and they move along for unloading thanks to the inclination.

Advantages and features

- Reduced loading and unloading times

- Increased storage capacity in a warehouse with adjustable pallet racking

- Enabling of loading and unloading aisles reduces risks for the operator

- Can be automated