The requirements of a fleet management system are often very specific: Every business offers a different working environment for the industrial trucks in a fleet. Accordingly, you can combine the individual function modules of Linde connect to form one system that optimally meets your individual requirements.

CONNECT:AC – ACCESS CONTROL

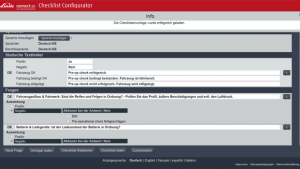

With connect:acoperators control access to your fleet: Who is currently at the wheel of which forklift truck? connect:ac provides the foundation for the planned fleet deployment.

CONNECT:DT – CRASH DETECTION

connect:dt documents the use of the fleet forklift trucks: Was a forklift truck being used a lot, or was it often not in use? Were there any accidents? Is the forklift truck functional?

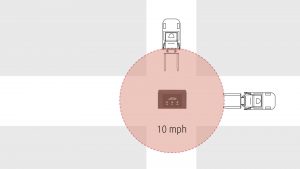

crash detection—The Electronic Damage Monitor

Was there an accident? Is part of the company site uneven? Is a driver driving without care? connect:dt crash detection records the time and severity of heavy shocks which could lead to forklift truck damage.

- Identification of danger points or floor damage on the company site

- Intentional misuse or irresponsible driving can be attributed to individual drivers

- Reduction of damage due to improper use

- Reduction of repair costs

- Early detection of forklift truck damage

- Automatic speed reduction of the forklift truck can be set

- Recording threshold can be set individually

- Determination of driver in the event of accidents or building damage

- More conscious driver behavior with the forklift trucks

- Improved safety on the company site

- Also available for retrofitting

operating hours – The Digital Driving Logbook

Is a forklift truck rarely used? Will it soon exceed the operating hours agreed upon with the leasing partners? With connect:dt operating hours, fleet managers can regularly determine the deployment duration of your forklift trucks.

- Automatic collection and transmission of the operating hours

- Read-out interval can be set individually

- No expense for manual recording of the operating hours

- No disruption of operational processes

- More transparency

- Improved operational planning and optimized fleet utilization

- Better scheduling of service intervals

- Avoiding unnecessary forklift truck down time

- Early identification of bottlenecks

- Warning if hours are exceeded

- Reduced overuse of the forklift trucks

- Reports possible for individual forklift trucks

- Data transfer via mobile telecommunication network, no additional infrastructure

- Also available for retrofitting

trouble codes – Automated Error Transmission from the Forklift Truck

Does a wearing part need to be replaced? Should a forklift truck be taken out of operation as a precaution? connect:dt trouble codes provides qualified information on errors on the forklift truck, even those which will not immediately limit performance.

- Early detection of malfunctions or damage

- Enables preventative servicing

- Reduces forklift truck down time

- Improved availability of the forklift trucks

- Optimizes service processes with reduced repair time

- Transparency with error sources

- Automatic information possible from the service organization

- Automated e-mail reports

- Also available for retrofitting

CONNECT:AN – USAGE ANALYSIS

With connect:an fleet managers analyze and monitor the performance of their fleet: How often does a forklift truck drive or lift? How much energy is it using?

CONNECT:ZI – ZONE INTELLIGENCE

With connect:zi industrial trucks can be managed more safely and transparently worldwide: How many forklift trucks does each location have in use? Where is each forklift truck currently located?