Autonomous trucks or facilities have long been used in intralogistics. But the increasing digitalization of business processes gives a new dynamism to automation: Automated systems lend themselves to seamless integration with IT processes, and thus take efficiency to a whole new level. All the same, complex systems such as fully automated shelf warehouses or classic DTS applications are not cost-efficient options in every logistics or production working environment. The requirements just keep increasing: Autonomous machines must be able to work in environments alongside people, and assist them in their work, without the risk of accidents. They ought to be able to communicate with other facilities in the infrastructure in real time, in order to ensure a smooth workflow. In addition, in many industries the production and logistics processes change just as dynamically as the products and goods themselves.

Smart automation with Linde

On the basis of a wide range of trucks, and navigational technology that does not require any fixed installation of infrastructure, Linde offers flexible and scalable automation solutions. They can be perfectly tailored to specific requirements – even for smaller companies – in order to automate anything, from individual steps in a process to complex material flows, in a cost-effective manner.

LINDE ROBOTICS

A smart, integrated solution

The advanced robotics technology allows the user to enjoy significant competitive advantages, while at the same time guaranteeing a high degree of flexibility in operational procedures. Highly developed safety systems and versatile, interface-capable software allow for fully integrated solutions: People and machines can interact safely and efficiently.

Why robotics?

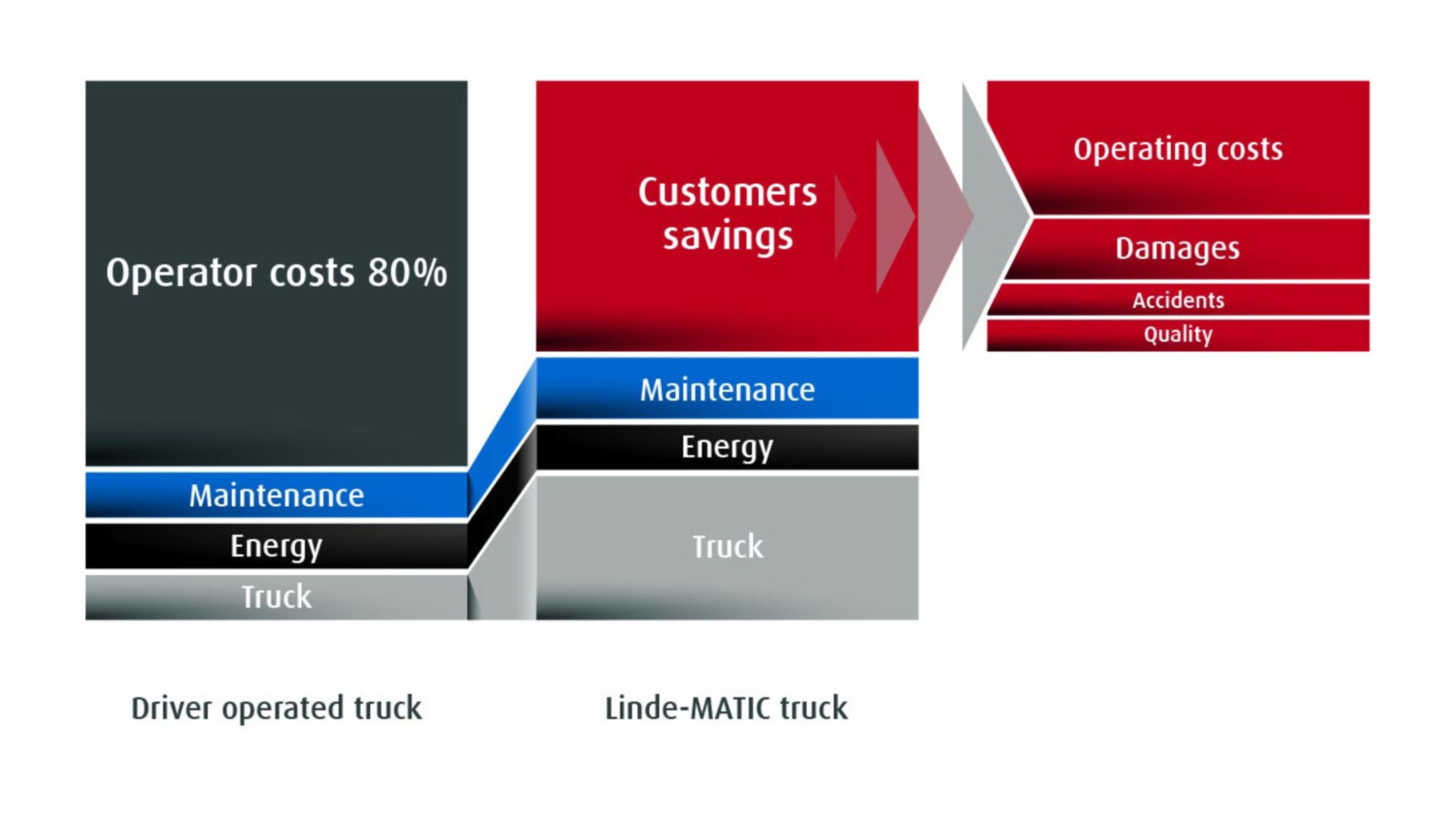

This new generation of autonomous work tools carries out repetitive handling processes independently and reliably. They increase productivity and reduce costs. Damage to goods and facilities is reduced, and the robotic forklifts perform tasks which are tiring and uncomfortable for human operators. Furthermore, the efficiency of the material flow is increased, because job allocation and routes are optimally determined and interwoven with related tasks.

COMPETITIVE

The most cost-effective solution

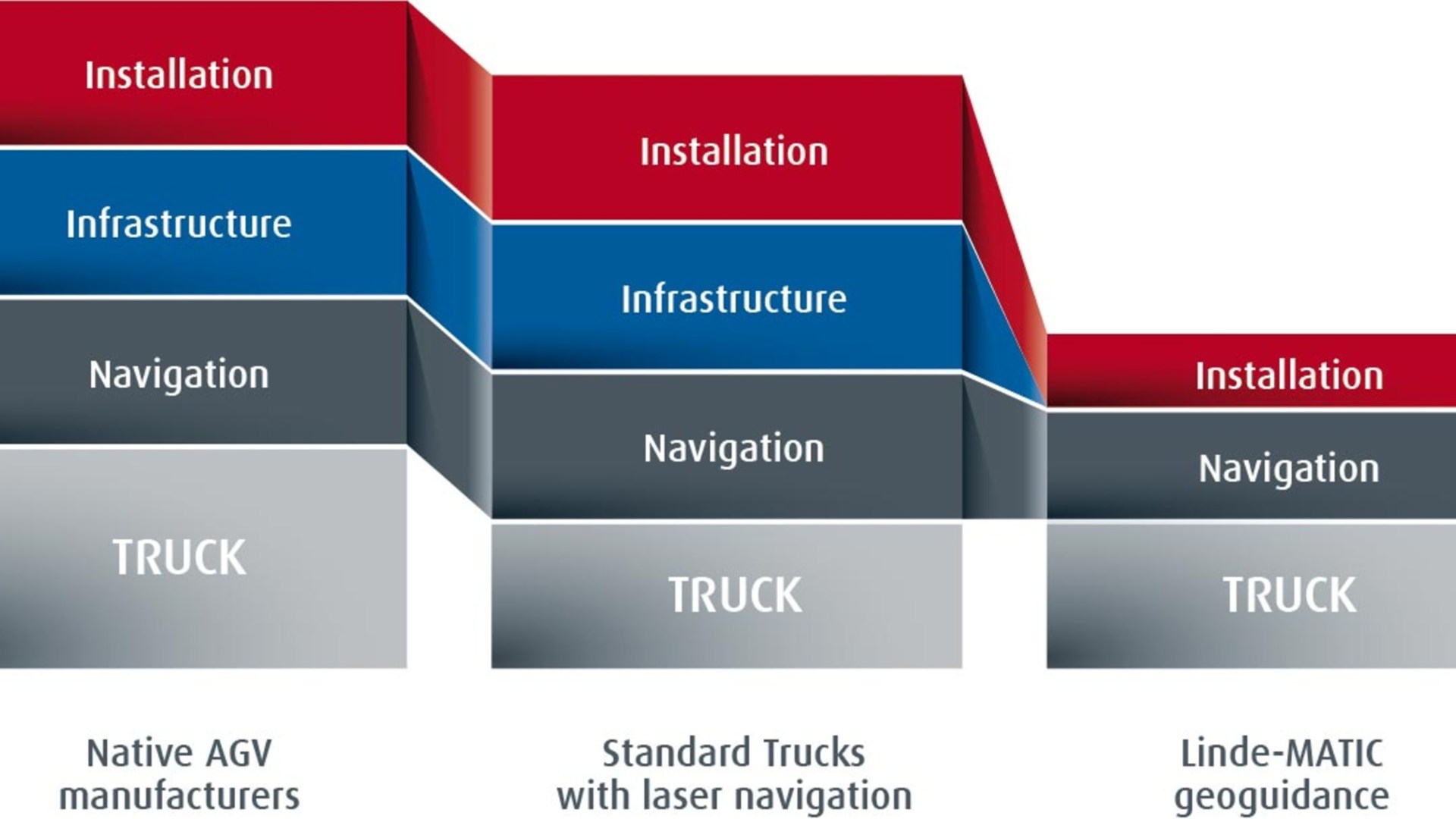

The basis of every robotics solution is the tried and tested standard trucks from Linde’s serial production range. Together with innovative navigation technology, which allows the robotic trucks to orient themselves without mirrors or tracks, Linde’s MATIC range offers a reliable automation solution that helps customers to optimize their internal material flow and significantly reduce costs.

Compared to other driverless systems with DTS or standard trucks:

- Lower installation costs

- Significantly lower running costs

FLEXIBLE

NO INFRASTRUCTURE

The navigational technology does not require any fixed installation of infrastructure such as tracks or mirrors. The MATIC models can therefore simply be integrated into existing storage or production facilities.

QUICK INSTALLATION

The system recognizes structures such as racking, walls, equipment and machines. This data is compiled in a two-dimensional map, on which routes and action points such as storage spaces and transfer stations are defined. New routes or spatial alterations are quick and easy to input.

SCALEABLE SOLUTION

The technology is equipped with all necessary interfaces in order to smoothly interlink automation solutions using either individual or fleets of MATIC trucks with the customer’s IT and operational processes.

COMPREHENSIVE INTEGRATION

The supervisor software controls the robotic fleet in real time. It monitors routing and allocates tasks. In addition, the software controls interaction with roller shutters, packing machines, conveyor belts, and production machinery. The entire application can interact directly with ERP (Enterprise Resource Planning) or WMS (Warehouse Management System) applications.

Real-time localization

The robotic trucks use the map to determine their position in the area. For this purpose, they compare the reference map in real time with the structures around them that the navigation laser currently recognizes.

SAFE AND PRODUCTIVE

The best of both worlds

The basic models in Linde’s MATIC product line are already equipped with numerous safety features. With additional camera- and laser-supported spatial monitoring, the robotic forklifts always move around safely and without significant losses in productivity both when interacting with people and in traffic with other trucks,

because the safety control of MATIC forklifts reacts dynamically: when an obstacle is recognized, the truck reduces its speed, and simply stops if the person or truck in its way stays there. Even then, it will automatically resume its course when the obstacle has left the monitoring zone of its lasers and camera.

Furthermore, the robotic trucks can be operated manually at any time. If someone operates the control unit directly, then automatic operations are immediately ceased, and the truck can, for example, be moved out of a dangerous area in an emergency, or be used for an important task outside of its automated work cycle.

Comprehensive safety features for cooperative work

- 3D camera for obstacle recognition

- Lasers on front and back for obstacle recognition and load detection

- Visual and acoustic warning systems

- Emergency stop buttons on both sides

LINDE MATIC RANGE

With high- and low-platform pallet trucks, tow tractors, counterbalanced forklifts, and a high-functionality truck for work in narrow aisles, the autonomous MATIC range covers 80 percent of all handling tasks in production and storage facilities.

Five advantages of geonavigation from Linde Robotics

- Networked: The spectrum ranges from implementation without any system connection, to extensive networking with operational systems, machines, and facilities.

- Safe: The comprehensive equipment such as scanners and cameras guarantees traffic safety, even in mixed working conditions.

- Simple: The innovative navigational system with modern Light Detection and Ranging (LIDAR) technology requires no additional expensive infrastructure.

- Flexible: Routes and reference points can be adapted to changing operational conditions at short notice.

- Transparent: The system generates valuable data, which can be used to help precisely optimize the productivity of logistical processes.

How does this technology work?

All the necessary structural measures for this technology can be implemented quickly: At regular intervals in narrow aisles, either RFID tags are fixed to the floor or barcodes are mounted on the shelves. While driving past, the scanning equipment on the truck reads the dataset on the RFID tag or barcode, thereby allowing the control system to determine the truck’s position in the aisles.

The central system sends target coordinates for the drop-off or picking-up point to the receiver in the truck via a WiFi network. On the way to its destination, the truck then continually checks its current position against its specifications, and determines the best combination of traction and lift movement in order to reach its desired position.

ADVANTAGES OF NARROW AISLE NAVIGATION

The truck goes where it has been instructed to via the quickest possible route with the least possible expenditure of energy. The result is time saving of up to 25 percent, and a significant increase in throughput.

The system assists the driver, and via a display shows them the exact pallet location for a particular product. The driver only has to activate the driving function. This rules out the possibility of a pallet being stored in the wrong place.

The aisle safety assistant, installed as standard with the narrow aisle navigation technology, recognizes marked bumps in the floor as well as obstacles on the shelves, on the floor, or on the ceiling, and limits certain driving functions – such as speed, lifting height and fork extension – in those areas.