-

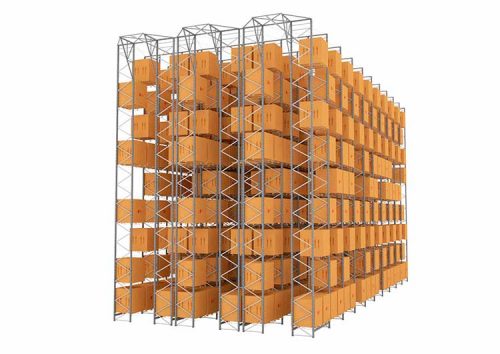

This type of racking is designed to store pallets in a mechanical and functional way using forklifts. These forklifts access goods through aisles parallel to the racks. The use of adjustable racks for palleted loads is a logistical solution which can be adapted to the dimensions of the unit loads and the forklifts. Efficient, resistant, easy-to-assemble, and with simple load level regulation, this system adapts to any type of product, both by weight and by volume. These systems can be adapted for picking.

Advantages and features

-

- Adapts to any type of unit load and forklift

- Allows direct and immediate access to goods

- Quick and efficient assembly, disassembly and replacement of parts

-

-

Automated pallet storage systems are solutions using stacker cranes or other similar automated mechanisms for handling loads. They offer high density storage thanks to the reduction of operating aisles and to their capacity for increasing in height. They also use minimum response times. Their reliability permits an immediate inventory of stored products and minimises mistakes in the handling of loads. Structures for automated storage can be simple or double-depth.

Advantages and features

- Offers maximum reliability and stock control

- Favours productivity

-

-

DELIVER GOODS QUICKLY, SAFELY, AND EFFECTIVELY

The CiTi one pallet truck is ideal for rapid goods deliveries by truck and ensures efficient processes, even if the street or sidewalk are uneven and narrow. This is because of the wheels and drive of the pallet truck: The load wheels pivot, at the same time, the drive wheel with integrated motor has a large diameter. This helps the pallet truck to manage higher curbs. In addition, the compact truck can be maneuvered effortlessly, because the operator controls all movements and the brakes easily using their thumb on the EasyControl joystick. The parking brake stops the truck safely on gradients or on truck hoisting platforms. The electric pallet lift truck CiTi one has a lifting capacity of 500 kg.

-

Rack clad warehouses can be made up of any type of storage system as their main feature is for the racking to form part of the building structure. In this system, the racking not only supports the load of the stored goods, but also the load of the building envelope, as well as external forces such as wind or snow. This is the reason why rack clad warehouses represent the concept of optimum use of a warehouse: in the construction process, first the racking is assembled, and then the building envelope is built around this structure until the warehouse is complete. Most rack clad warehouses are equipped with automated systems and robotic equipment for the handling of goods, especially of if they are multitier. In addition, AR Racking complies with the EN-1090 CE marking standard, mandatory for all manufacturers of self-supporting industrial steelwork structures installed in the European Community, as established in Regulation 305/2011 of the European Parliament.

Advantages and features

- Storage at heights.

- Optimum use of space.

- Maximum endurance capacity.

-

Coil Racks or Coil Supports permit the simple storage of any material rolled in coils (Cable, rope, cloth, etc.). This storage system is mounted on an adjustable pallet racking structure which is adapted with specific supports for the storage of coils. The industrial coil racks make adjustable pallet racking more versatile and complement other storage systems.

-

Compact and agile for double the handling performance

The pedestrian double stackers D06 and D08 are ideal for easy logistical use, for example where there are rapid transport and order picking processes in the supermarket. Despite a lift height of 2024 mm, the trucks are very compact. This makes working in narrow warehouses easier. And using the innovative creep button, the truck can still maneuver precisely even when there is very little space available. The innovative caster system provides even more safety. It improves traction and stability even on uneven floors. The operator has a good view of the load and the path through the special mast construction. The D06 and D08 pallet stackers can simultaneously transport two palettes with a total capacity of 600 kg or 800 kg respectively. -

Efficient pallet handling on two levels

The D10 pallet stacker from Linde Material Handling enables a fast material flow even in cramped and highly frequented environments. It can transport two pallets simultaneously with a total weight of 2,000 kilograms using the forks and load arms. The innovative rollers ensure stability whilst transferring goods as well as when loading and unloading. Thanks to the narrow chassis, measuring at just 720 mm, and the creep speed function, precise control in narrow aisles is possible. The long tiller with low mounting point always ensures sufficient safety clearance between the truck and operator. The truck adjusts its speed and lifting functions in proportion to the tiller angle.

-

Move comfortably through the warehouse with two pallets

The pallet stacker D10 AP from Linde Material Handling can be used as a pedestrian or ride-on truck, providing flexibility. When transferring goods, it accelerates to a maximum of 10 kilometers per hour while the operator stands on the fully suspended, folding stand-on platform. Thanks to its narrow chassis, the truck is particularly suitable for loading and unloading trucks and for use in confined warehouse environments. The double-deck pallet stacker can transport two pallets at the same time with a total weight of 2,000 kilograms. The Linde OptiLift system ensures easy pallet handling and enables fully proportional lifting and lowering thus protecting the load. Since the rotation speed of the lifting motor is adjusted accordingly, lifting movements are extremely precise, quiet and smooth. Two folding side guards keep the operator within the truck's chassis contour at all times. In addition, the creep speed and automatic brake function ensure optimum safety and high productivity.

-

Agile with two pallets

The D10 FP pallet stacker is a compact and powerful double deck loader. With a chassis width of just 720 mm and electric power steering, it is extremely maneuverable even in the tightest of spaces. It is therefore particularly suitable for loading and unloading and for medium-to-long pallet transfer. The powerful 2.3-kW engine enables powerful acceleration up to 10 km/h. The D10 FP can pick up two pallets at the same time, which guarantees maximum handling performance. The truck is equipped with a steel chassis skirt to protect the driver from minor impacts.

-

Agility combined with high drive capacity

The electric double stackers D12 - D14 are very flexible when it comes to storing and removing goods, for longer transport distances with two pallets or for quick order picking processes. A high working speed is also guaranteed through the Linde OptiLift controls. It enables precise lifting and lowering of the load. At the same time, the operator maneuvers the truck with no effort using the electric steering unit and adjustable steering resistance. The truck is also very agile with its compact chassis. Thanks to the high performance 3 kW three-phase motor, the double stacker can reach a maximum speed of six kilometers per hour. Its lifting capacity is 1200 to 1400 kg. -

High Throughput Performance Even in Confined Spaces

The D12 R double pallet stacker transports two pallets of up to 1000 kg each at the same time and achieves a speed of up to 10 km/h with its 3 kW three-phase AC motor. This makes it particularly suitable for fast transport over medium and long distances where high throughput rates are required. Thanks to the initial lift, the vehicle is also suitable for loading and unloading trucks. Precise control enables particularly safe, comfortable and productive handling. Thanks to its compact chassis and excellent maneuverability, the D12 R can be maneuvered safely and quickly, even in confined spaces. The high seating position, which is perpendicular to the direction of travel, provides the driver with the best possible visibility of the loads and the surroundings.

-

Transport two pallets in the tightest spaces

The D12 S/SF pallet stackers have a chassis that is narrower than a pallet. So these trucks can transport two pallets at a time, and maneuver within the tightest spaces. In addition, the operator has a high stance and thus a free view of the fork tips. This makes load handling easier. The operator platform is separated from the chassis by a layer of rubber. This protects the body from strong vibrations during travel so the operator can concentrate longer. Linde offers the D12 pallet stacker in two standard versions: In the S model, the operator is standing at a right angle to the direction of travel and has a good view to the front and back. In the SF model, he is standing frontal to the direction of travel and always has the load in view. Both models have mast variations for various load heights. The pallet trucks have a lifting capacity of up to 2000 kg. -

The Drive in Racking System is a high density storage solution that maximizes available space and height in the warehouse by reducing the forklift operating aisles. It is made up of an easy-to-assemble and -reset modular structure, which makes it easy to maintain. Compact racking can be either Drive in racking, with only one access aisle, where the last load in is the first one out, or Drive through racking, with an entrance and exit, where the first load in is the first one out. It is the optimal and most common pallet storage system when you need to store homogeneous products with a large number of pallets of the same reference. This compact system is appropriate where space utilisation is more important than selectivity of stored loads.

Advantages

- Space optimization above 80%.

- Low maintenance and low assembly costs make this system one of the most cost-effective systems.

- Structure compatible with other storage systems.

- Provides maximum performance, and utilisation can be over 80% of the available space.

- Enables clearly arranged logistics management with full control of inventories as well as traffic and service flow.

- Designed to allow for quick reconfiguration of the structure for extension or change as needed.

- Ideal for storing low-rotation loads of the same type.

- Eliminates the service aisles found with a conventional pallet racking system.

- Maximised storage floor and height.

- Easily assembled modular structure.

- Trucks enter the system for loading.

- Includes various accessories to increase safety.

- Maximisation of space

- Products of the same type

- Low stock rotation

-

VERSATILE LOAD HANDLING IN CONFINED SPACES

The compact E10 electric forklift truck from Linde Material Handling combines high manoeuvrability with a wide range of application options. With a lifting capacity of up to 1000 kilograms, it is the smallest model in its series but is suitable for a multitude of applications thanks to its optimal weight distribution. Its short wheelbase, compact construction with a width of just 828 millimetres and optimal steering concept enable stacking, transporting, order picking, loading and unloading, even in the tightest spaces. Automatic speed reduction when cornering also gives the E10 high stability.

-

MAXIMUM FLEXIBILITY, MINIMUM ENERGY CONSUMPTION

The three-wheeled E12 – E20 EVO trucks (including NEW Linde EG Models) allow for precision load handling in even the tightest of spaces. Thanks to the central pivot axle, the driver can turn up to 180 degrees with a single steering wheel movement. Two three-phase motors integrated in the front axle guarantee a powerful drive, offering outstanding acceleration and top speeds, powered by 48 or 24 volt batteries. Linde energy management ensures the batteries are used to full capacity, minimizing consumption. What's more, all E12 – E20 EVO forklift models can also be equipped with Lithium-Ion batteries that allow for efficient multiple-shift operation without the need to change batteries.

-

OPTIMAL MOBILITY AND STABILITY

The four-wheeled E16 – E20 EVO trucks allow for precision load handling in even the tightest of spaces – with even greater stability. Linde's innovative combi-axle allows the rear wheel turntable axis to be turned through up to 175 degrees, enabling the truck to maneuver on the spot without damaging the flooring. The electric forklift truck is equipped with the Linde compact axle: an integrated unit comprising two powerful drive motors, maintenance-free brakes, and performance parts installed directly on the axle that guarantee outstanding operational performance, while rapid battery changing and high truck availability is assured thanks to the optional on-board charging device. All this allows electric forklift trucks to offer maximum performance with outstanding energy efficiency. -

HIGH PERFORMANCE INDOOR SPECIALIST

Safe and quick in tight spaces

The E20 – E35 electric forklift trucks are ideally suited to indoor use. Their compact design and agility ensure high handling capacities even in tight spaces. In particular, the twin-motor front-wheel drive together with the Linde combined steering axle facilitates exceptional maneuverability. Thanks to a common platform for both electric and combustion engine trucks, the electric forklifts further impresses with improved ergonomics and by a generous driver workspace. The synergies of this platform means the electric forklift truck gives the driver significantly more space and an especially comfortable operating experience.

-

VISIBILITY WITH HIGH HANDLING PERFORMANCE

Revolutionizing operational visibility, the new Linde E20 – E35 R roadsters are powerful, versatile forklift trucks suitable for loads of between 2000 and 3500 kilograms. The driver has an all but unobstructed view of their work station, load, and surroundings thanks to the truck's unique design, that sees the cab roof connected directly to the lift mast via the tilt cylinder, avoiding the need for an A-pillar. The two powerful drive motors of the Linde compact axle, the maintenance-free brakes, and other smart performance parts form a single unit that gives this model series its optimal maneuverability and handling. What's more, the new Linde energy management system ensures low energy consumption.

-

OPTIMAL PERFORMANCE FOR DIVERSE APPLICATIONS

Suitable for loads between 3500 and 5000 kilograms, the Linde E35 – E50 series of powerful electric forklift trucks meet a wide range of specifications in order to optimally cater for customer requirements. These include, for example, compact models for areas where space is at a premium or tall trucks with a long wheelbase for tall, bulky loads. High handling performance is guaranteed, thanks to the two powerful three-phase motors of the Linde compact axle and dual pedal control, while features such as the overhead tilt cylinders, electronic traction control, and optional on-board high frequency charger bear testament to Linde's commitment to safety and cost-effectiveness.

-

ELECTRICAL POWER FOR HEAVY LOADS

The powerful Linde E60 – E80 forklift models are ideally suited for heavy loads weighing in at between 6000 and 8000 kilograms. The compact axle comprises two powerful drive motors that harness the power of maintenance-free brakes and smart integrated performance parts. Low energy costs, emission-free drive, and minimal maintenance costs all guarantee extremely cost-effective truck usage, while the Linde energy management technology ensures smart, transparent energy consumption. Plus, a display shows residual capacity to allow greater planning accuracy.

-

HANDLE HEAVY LOADS PRECISELY AND SWIFTLY

The H100 – H180 D IC trucks can transport even the heaviest of loads precisely, swiftly, and cost-effectively, securing a competitive advantage in terms of handling performance. All this is made possible by Linde's hydrostatic drive, which allows heavy trucks to be moved with millimeter precision. The driver can quickly and smoothly shift between backward and forward movement, while modern diesel engines guarantee high torque and low fuel consumption.

-

MAXIMUM WORKING CAPACITY AT LOW SERVICE COSTS

The Linde H14 – H20 EVO IC trucks can go the distance even in the toughest conditions. The combination of the hydrostatic direct drive, robust engines, and the Linde Load Control facilitates both rapid and precise operation and exceptional handling performance. At the same time, service costs remain low, as the hydrostatic drive operates without a transmission, clutch, or drum brakes, meaning it is maintenance-free. Choose from a range of cost-effective, low-emission diesel, propellant gas, and natural gas engines.

-

NETWORKED AND EASY TO SERVICE FOR MAXIMUM EFFICIENCY

The IC truck H20–H35 is powerful, easy to operate, robust, low-maintenance, and versatile. The forklift for loads between 2,000 and 3,500 kilograms is particularly well suited for high loads in multi-shift operation and assignments in the harshest outdoor conditions. Hydrostatic drive, dual pedal control, Linde Load Control, and optimal visibility ensure precise interaction between man and machine. Design details combined with intelligent assistance systems guarantee the highest possible levels of safety. The H20–H35 can be integrated into software systems, e.g. for fleet management, via wireless data transmission. The truck fulfills the latest EU 5 (2016/1627) exhaust emission regulations and it even undercuts the required emissions massively.

-

PERMANENT PEAK PERFORMANCE UNDER TOUGH CONDITIONS

The quality of the H40 – H50 IC trucks really comes to the fore in especially long and challenging applications. Powerful engines, a hydrostatic direct drive, and the Linde Load Control lift mast control system all ensure consistently high operational performance. At the same time, the truck only rarely needs to be taken off duty for servicing, as the bearings of the axles and tilt cylinders, for example, do not require maintenance. The same applies to the robust direct drive that operates without a transmission or drum brakes. Enhanced safety is assured thanks, among other things, to the Linde Protector Frame, that sees the roof and frame form a single robust unit.

-

IMPRESSIVE OPERATING PERFORMANCE – MINIMAL MAINTENANCE BREAKS

Safe handling and high handling performance – with the H50 – H80 IC trucks, the two go hand in hand. These robust trucks are ideally suited to heavy-duty applications with large loads. The protective driver's roof and frame form a single compact unit to ensure greater safety, while the slim profile of the lift mast improves the driver's vision. Powerful engines, the hydrostatic direct drive, and the Linde Load Control lift mast control system all guarantee high operational performance. Plus, the hydrostatic drive operates without a transmission, clutch, differential or drum brakes – reducing servicing time and further increasing handling capacity.

-

COST-EFFECTIVELY TRANSPORT HEAVY LOADS

The HT100 – HT180 Ds IC trucks are fast and efficient when handling heavy loads: a fact guaranteed by the well coordinated combination of modern diesel engines, transmission, and hydrodynamic drive. This technology ensures exceptionally strong handling performance, particularly for transport over long distances. What's more, drivers of trucks in this class benefit from excellent all-round visibility, as essential components, such as the mast and counterbalance, have been designed for optimal vision.

-

Work effectively and with a view in the high shelving

The Linde K man-up turret truck enables high turnaround capacity for order picking and handling processes in high-shelving warehouses. The powerful drive trains make this possible: The truck can move and lift at the same time. Also, even at high lift levels the speed remains high and a high level of residual lift capacity is available. Various assistance systems are available that help to navigate accurately through warehouse or to avoid obstacles. Not least, Linde System Control improves the process: Dependent upon the version, the system adjusts lift and travel speed according to the weight being transported. There are various versions or the mast, chassis, battery and cab for the very narrow aisle trucks that can be combined according to usage requirements. -

Reliable logistics in narrow aisle warehouses

The Linde K-MATIC autonomously driven turret truck is suitable for loads of up to 1,500 kg and lift heights of up to 12 meters. The intelligent geo-navigation system guides the K-matic safely without additional guide rails in the floor or laser reflectors, and is compatible with all common narrow aisle applications. Whether as an individual truck carrying out defined process steps, or as part of a centrally controlled fleet of robotic trucks, the superior functionality of the K-Matic provides high handling performance even for complex operating requirements. When doing so, the truck interacts seamlessly with the customer’s infrastructure, such as belt conveyors or packing stations. As an autonomous logistics truck, it mitigates damage to loads and pallets and is particularly well-suited to the handling of high-value goods. Quick and easy to maintain, the robotic truck can be relied upon to be ready for use round-the-clock and can also be operated manually by a driver. View all forklifts for sale. -

Effective Load Handling for Low Lift Heights

The Linde Material Handling L-MATIC pallet stacker is suitable for storage or removals at low level. It tackles loads of up to 1,200 kg and lift heights up to 1.9 meters. Thanks to infrastructure free geo-navigation, the L-MATIC can be used flexibly as an individual truck or as part of an automated fleet. When operating in this manner, the robotic forklift is able to integrate safely and efficiently with people, non-automated trucks or the customer’s infrastructure, such as belt conveyors or packing stations. Furthermore, manual operation is possible at any time, used to, for example, move the equipment away from a dangerous zone quickly in the event of an emergency, or to use the truck to carry out another short-term task. -

Effective Load Handling for Low Lift Heights

The Linde Material Handling L-MATIC pallet stacker is suitable for storage or removals at low level. It tackles loads of up to 1,200 kg and lift heights up to 1.9 meters. Thanks to infrastructure free geo-navigation, the L-MATIC can be used flexibly as an individual truck or as part of an automated fleet. When operating in this manner, the robotic forklift is able to integrate safely and efficiently with people, non-automated trucks or the customer’s infrastructure, such as belt conveyors or packing stations. Furthermore, manual operation is possible at any time, used to, for example, move the equipment away from a dangerous zone quickly in the event of an emergency, or to use the truck to carry out another short-term task. -

Small turning radius for optimal maneuverability

The counterbalanced pallet stackers of the L06 - L16 AC are an effective handling solution if there is too little space available to use a truck or if the transport distance is too short for the electric forklift truck. The operator profits from easy steering and a small turning radius. Automatic speed reduction when cornering and a good view of the load through the mast are additional safety features. The slim chassis is strong and torsion-resistant. -

Agile and versatile thanks to the slim chassis

Whether storing or picking, distance transport or pallet transfer: The electro pallet stackers L10 - L12, with their slim chassis and good clear view masts make many maneuvers easier, especially where there is little space available. The operator profits from the tiller being mounted at a low point, which guarantees a safe distance from the stacker. There is also a creep speed function for very slow and tight maneuvers. Here the tiller is in an upright position. Overall the truck operates completely intuitively. All control elements are ergonomically arranged within the tiller head and provide for fatigue-free work. -

The specialist for narrow aisle and block stacking applications

The electro straddle stackers L10 - L12 AS quickly and flexibly lift pallets with closed bases and various type of small containers, even if used in narrow aisles. For this purpose, the trucks have a small turning radius. The spacing of their straddle legs can be flexibly adjusted. L10 AS and L12 AS accelerate freely with a three-phase motor. A SafetySpeed function automatically adjusts the speed to the tilting angle of the tiller. -

Agility combined with high drive capacity

The electric double stackers L12 - L14 AP/SP, D12 - D14 AP/SP are very flexible for storing and removing goods, for longer transport distances with two pallets or for quick order picking processes. A high working speed is also guaranteed through the Linde OptiLift controls. It enables precise lifting and lowering of the load. At the same time, the operator maneuvers the truck with no effort using the electric steering unit and adjustable steering resistance. The truck is also very agile with its compact chassis. Thanks to the high performance 3 kW three-phase motor, the double stacker can reach a maximum speed of six kilometers per hour. Its lifting capacity is 1200 to 1400 kg.