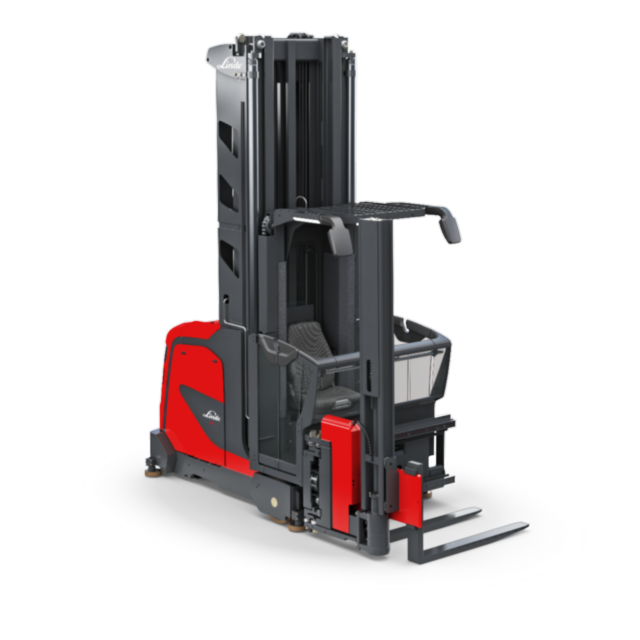

Work effectively and with a view in the high shelving

The Linde K man-up turret truck enables high turnaround capacity for order picking and handling processes in high-shelving warehouses. The powerful drive trains make this possible: The truck can move and lift at the same time. Also, even at high lift levels the speed remains high and a high level of residual lift capacity is available. Various assistance systems are available that help to navigate accurately through warehouse or to avoid obstacles. Not least, Linde System Control improves the process: Dependent upon the version, the system adjusts lift and travel speed according to the weight being transported. There are various versions or the mast, chassis, battery and cab for the very narrow aisle trucks that can be combined according to usage requirements.