With ease through narrow aisles

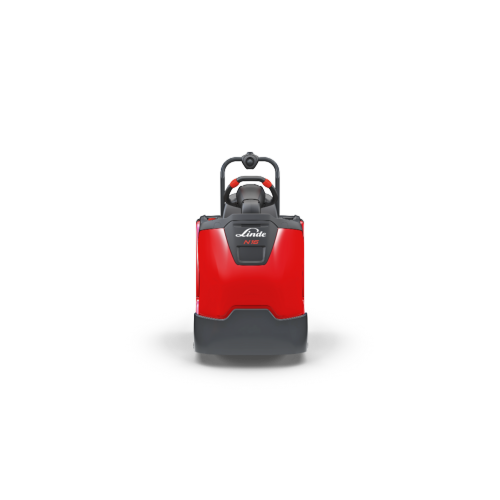

The MV01 task support vehicle is a compact vehicle whose manoeuvrability makes it suitable for a variety of applications in the warehouse. The wide range of additional equipment available allows the vehicle to be optimally adapted to any task, be it order picking up to the third rack level or warehouse maintenance. The platform can be raised to a height of up to three metres, allowing the operator to reach goods up to a picking height of 4.6 metres with ease. The stable mast secures picking on the second and third levels for a load capacity of up to 100 kilograms. Its overall length of just 1140 millimetres makes it highly manoeuvrable and facilitates steering manoeuvres in narrow aisles. This manoeuvrability relieves employees and contributes to higher handling performance in the warehouse. Thanks to the lithium-ion battery, the vehicle can be recharged at any time so that it is available to warehouse personnel without longer interruptions.