-

Quick and comfortable storage in medium lift heights

The L14 - L20 AP pallet stackers can be used for many applications and create efficient and quick processes in the warehouse. With a 2.3 kW three-phase motor, the truck achieves a maximum speed of 10 km/h with the platform folded down. It has a load capacity of up to 2000 kg. All of the control elements are located on the tiller head and allow for intuitive operation of the pallet stacker. The truck can also be controlled with very little effort thanks to the electric power steering. And using the Linde Load Control, any load can be handled sensitively and with precision. A scale installation shows the operator the load weight. -

Double load for higher productivity

The electro pallet stackers L14 – L16 AS AP/AS comes in two standard versions, so the user has a custom fitted and effective solution available for their area of operation: the SP version with a fixed platform for optimum comfort for longer distances or the AP version with a foldable platform for more flexibility during operation. This version of the truck is more compact. Both platform versions can be combined with the various vehicle versions such as the double stacker. The maintenance-free 3 kW three-phase motor achieves a maximum speed of 10 km/h regardless of load weight. The easy to use servo supported power steering creates more productivity. -

Fatigue-Free Working in All Situations

The L14 – L16 R pallet stackers can achieve lifting heights of up to 5,316 millimeters. Thanks to the optional initial lift and overhead guard, they are also suitable for safe loading and unloading of trucks via ramps or bridge plates. With a compact width of 820 mm, the truck is both maneuverable and comfortable. Due to a lateral and raised seating position, drivers have the best view of the loads and their surroundings. The vehicles are equipped with a powerful 3 kW motor and reach speeds of up to 10 km/h. In ECO mode, energy consumption is reduced by 12 percent.

-

Precise Movement of Light to Medium Loads

The L14 C pallet stacker is a flexible and efficient handling solution for the transport of pallets, gitter or pallet boxes. With the help of the OptiLift mast control, the storage and retrieval of light to medium-weight goods can be carried out smoothly, precisely and quietly. All control elements of the ergonomic tiller head can be conveniently operated with both hands. A hand guard on the tiller head protects the operator from injury. At the same time, the long and low mounted tiller arm ensures that it is at a safe distance from the truck. An effective parking brake holds the truck securely on a slope. A maintenance-free AC motor reduces operating costs. The L14 C pallet stacker transports loads with a total weight of up to 1,400 kilograms.

-

Electric Pallet Stacker with Ergonomic Platform

The L14 P electric pallet stacker from Linde Material Handling ensures precise stacking and transport, as well as a safe and efficient material flow. The truck can carry loads of up to 1,400 kg and reach a maximum speed of 6 km/h. Thanks to the fold-out platform, operators can cover short and medium distances in warehouses without any difficulties. The platform's special suspension eliminates any vibrations and shocks when on the move and the non-slip rubber mat ensures operators maintain a secure footing. The Linde OptiLift® control system is quiet and energy saving, and enables operators to handle loads with absolute precision. Thanks to this intuitive system, operators can control all driving and lifting maneuvers with just one finger, while maintaining a good view through the mast. A creep speed button on the ergonomic tiller head also reduces the speed to 1.5 km/h in pedestrian truck mode, making maneuvering in tight warehouse environments even safer.

-

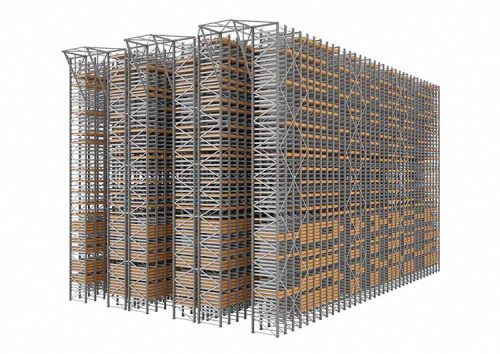

This storage system is ideal for warehouses where stock turnover control and space saving are critical. The compact structure uses slightly inclined roller beds on each level to allow unit loads to be moved more easily. AR Racking offers two types of live pallet racks: Gravity Fed Used for the FIFO system (First In, First Out), in which the loading area is at the opposite end to the unloading area, and the goods move along this space thanks to the inclined roller bed system. Push-back. Mostly used for the LIFO system (Last In, First Out); this has only one loading and unloading point: the goods are stored by pushing the previous ones towards the back and they move along for unloading thanks to the inclination.

Advantages and features

- Reduced loading and unloading times

- Increased storage capacity in a warehouse with adjustable pallet racking

- Enabling of loading and unloading aisles reduces risks for the operator

- Can be automated

-

This system permits the manual storage of medium and small materials. This is a versatile racking that adapts to any type of unit load and facilitates direct and immediate access to stored SKUs. Its easy assembly and the option to incorporate accessories, such as platforms, make it possible for this racking to increase in height without compromising performance. The design, manufacture and assembly can be customised to suit client requirements and their professional sector.

Advantages and features

- Adapts to all load types

- Resistant and robust

- Fast assembly and replacement of components

-

EFFICIENT MATERIAL FLOW IN PRODUCTION

The Linde Material Handling LT06 – LT20 series logistics trains are designed for packaged material transportation in indoor and outdoor areas, and under demanding industrial conditions. It boasts robust SE tires and a lift height of up to 200 mm, and it is possible to move loads of up to 2,000 kg per trailer, with up to 6 trailers. With different frame variants and trailer types, Linde logistics trains can be designed to adapt to specific production requirements. Thanks to the flat construction of the C-frame trailer, the transportation of long items is also possible. The trailers are available in C-frame and hanger frame variants, as well as in a platform construction.

-

Flexible transport, lifting, and order picking

The pallet lift trucks M10 X and M10 XE can lift their forks via scissor lift to a height of 800 mm and have a very compact design. This is why these trucks are used flexibly in transport tasks, as mobile working platforms, or for occasional order picking in the tightest of spaces. Linde offers two versions: The M10 XE model has an electric lift drive. The operator doesn't have to use any strength to lift or lower the load. In the model M10 X, lifting is initiated manually by the operator using the tiller. The direction of movement can be changed using a single lever located on the handle. Both models have a rugged, warp resistant chassis and a reinforced tiller. The pallet lift truck with scissor lift M10 X/XE can carry and lift a maximum load of 1000 kg. -

RAPID TRANSPORT OF HEAVY LOADS OVER SHORT DISTANCES

The pallet lift truck M25 has a rugged construction and will not bend under heavy loads. Its steel chassis can take about 25 percent more weight than comparable models of this size. The hydraulics of the M25 are protected from dust and are well suited to long, hard working days, with a minimum of service. The drive wheels and rollers increase handling capacity with their low rolling resistance. The tiller also has a large steering angle on both sides. It's therefore easy to manoeuvre the M25 in a tight space, such as the truck loading bays. A broad tiller handle protects the hands from injury. The pallet lift truck M25 has a maximum load capacity of 2500 kg.

-

Weighing and transporting in one step

The pallet lift truck M25 Scale+ has a scale system with a tolerance of only 500 g. This means users are spared a trip to an external precision scale and save time when loading a truck. Linde also offers printers and memory cards if the user wants to store the measurement. For example, deviations from actual order quantities can be documented. The warp-free construction of the M25 Scale+ ensures high handling performance. In this way, the truck not only has an extraordinarily high load capacity for the class, but can also handle tough, continuous use with no need for servicing. The operator's hands are protected by a wide tiller handle. The M25 Scale+ pallet truck can transport weights of up to 2500 kg. -

Mezzanine floors can double and even triple surface area, increasing the usable surface in height by one or two levels inside a warehouse. They are independent structures, easy to assemble and adaptable to any space where the flooring can be made of different materials such as wood or tramex. Several accessories are available including handrails, stairs, unloading points, etc.

Advantages of the Mezzanine Floors

- Increased surface area of warehouses and stores

- Great variety of floor sizes and types

- Quick and simple assembly

-

The mini load automated storage system is the optimal solution for the storage of light and small unit loads with high stock turnover ratios. This system uses automated stacker crane mechanisms to handle loads, offering high performance and reduced carton storage and handling times. It is a high density system thanks to the reduction of operating aisles and maximized floor and height space. Reliability allows the daily inventory of stored products and minimises errors when handling loads.

Advantages and features

- Product-man system in which the operator does not move

- Increased productivity and efficiency

- Cost savings

-

Effective Combination of Picking and Transporting

The electric pallet stackers ML 10 and MM 10 are extremely versatile. For example, they can be used as an ergonomic order picker platform or for transporting lighter goods. During order picking, the operator lifts his work surface to a comfortable height, which protects his back. During the transport of goods, an initial lift provides more ground clearance. Unevenness or ramps are not a problem. It is also important that different mast heights are available. This enables the truck to be precisely adapted to the respective area of application. Safety is ensured by the long tiller arm, hand guards and an effective parking brake. The electric pallet stackers ML 10 and MM 10 have a maximum load capacity of 1000 kilograms.

-

This is a system where the pallet racks are placed on chassis or mobile bases guided through fixed tracks on the floor. The base of this type of racking is equipped with an electric motor and remote push-pull elements allowing the racks to move along the tracks in order to open only one forklift access aisle. It is a high-density storage system, providing simple access for conventional forklift pallets. Its versatility permits its adaptation to both the load type and the type of forklift.

Advantages and features

- Simplifies access to all pallets

- Significant energy savings

- Adapts to any space, weight, or size of the goods, and is compatible with other automatic or conventional storage systems

-

FAST GOODS TRANSPORT IN CONFINED SPACES

The MT12 pallet truck has a particularly compact design and is therefore very easy to handle – even when space is at a premium. This ensures fast handling processes in the retail trade, in narrow aisles or in production areas. The vehicle is equipped with a lithium-ion battery that can be easily replaced via plug-and-play. Charging takes place via an external charger at any socket. An effective parking brake holds the truck firmly in position when it is, for example, on an inclined truck loading ramp. The MT12 pallet truck has a robust chassis and reinforced forks and can therefore easily transport loads of up to 1200 kilograms.

-

Easy turning maneuvers in tight spaces

The MT15 electric pallet truck unfolds its potential above all on short distances and demanding terrain: narrow aisles, steep ramps and packed loading areas are no problem for the agile all-rounder. Its compact design, for example the truck’s length including the back of the fork at only 400 mm, makes it easy to maneuver in narrow aisles in the warehouse or in retail stores. As a light weight of only 180 kilograms, the pallet truck can also be used in mezzanine floors. The electric traction and lifting performance relieve the operator, who hardly needs to exert any force to transport loads weighing up to 1.5 tonnes. The long tiller protects the operator, as they’ll automatically keep a safe distance from the truck. The MT15 is particularly flexible with the lithium-ion battery, which allows intermediate charging.

-

The multitier or high rise aisles, designed for warehouses with limited floor areas but available height, are manual storage solutions that maximise warehouse space. They offer an optimum use of height with the creation of different levels of manual loading aisles at different heights accessible by stairs.

Advantages and features

- Optimum use of space at height

- Adaptability to goods and accessibility

- Option to incorporate mechanical means

-

With ease through narrow aisles

The MV01 task support vehicle is a compact vehicle whose manoeuvrability makes it suitable for a variety of applications in the warehouse. The wide range of additional equipment available allows the vehicle to be optimally adapted to any task, be it order picking up to the third rack level or warehouse maintenance. The platform can be raised to a height of up to three metres, allowing the operator to reach goods up to a picking height of 4.6 metres with ease. The stable mast secures picking on the second and third levels for a load capacity of up to 100 kilograms. Its overall length of just 1140 millimetres makes it highly manoeuvrable and facilitates steering manoeuvres in narrow aisles. This manoeuvrability relieves employees and contributes to higher handling performance in the warehouse. Thanks to the lithium-ion battery, the vehicle can be recharged at any time so that it is available to warehouse personnel without longer interruptions.

-

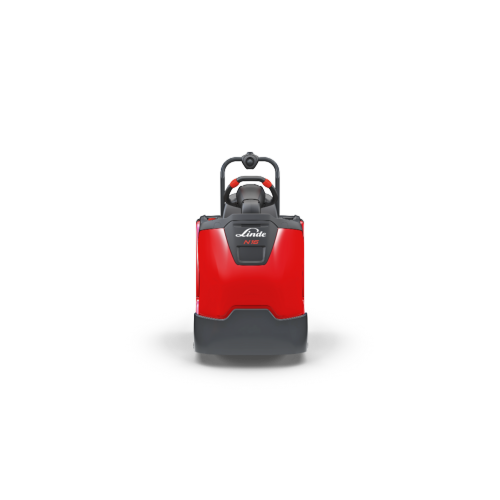

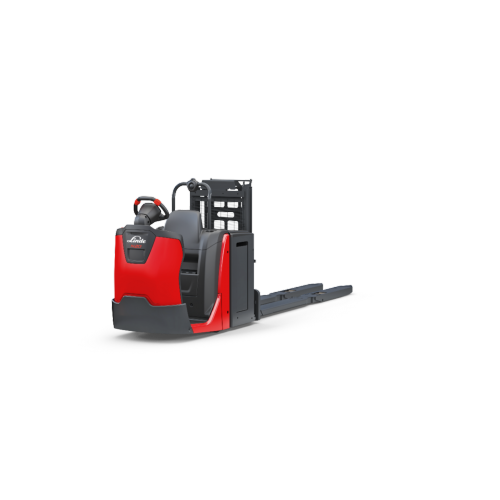

ERGONOMIC ORDER PICKING ON A PALLET

The N16 Li order picker from Linde Material Handling enables a particularly high picking output: As the operator platform is positioned in front of the battery, the driver has a good view of the warehouse environment. Even in narrow aisles, the operator quickly maneuvers the truck into the desired position thanks to the small turning circle. With the aid of the lift, the forks can be raised to an ergonomic height of up to 790 mm for loading. With the optional Autolift, the truck automatically lowers the forks in proportion to the increasing height of the load. This eliminates the need for manual operation of the lift and the operator always picks orders at the optimum height without unnecessary interruption. The entire operator platform is spring-loaded and absorbs vibrations and shocks during transport.

-

MANEUVERABLE AND ERGONOMIC WITH STANDARD DESIGN

The Linde N20 - N25 C low-lift order pickers are all-rounders in the warehouse thanks to their high loading capacity and dynamic driving characteristics. The long forks allow up to three pallets or four roll cages weighing up to 2,000 or 2,500 kilograms to be picked up simultaneously. The classic construction offers a clear all-round view and allows flexible maneuvering even in narrow warehouses via an intuitive steering wheel. With the aid of the 3 kW three-phase AC motor, the order picker accelerates up to 14 km/h. Maximum safety is ensured by the robust design and automatic speed adjustment. Special attention is paid to ergonomics: From low access to a cushioned platform as standard and a gentle backrest, the order picker relieves the driver of physical strain thus helping them to work more efficiently.

-

TRANSPORTING SENSITIVE GOODS ON TWO LEVELS

The N20 C D double-deck order picker is the ideal solution for efficient order picking and safe transport of pressure sensitive goods such as food. It can be used to pick up two pallets separately and transport them on top of each other to save space. Thanks to its compact design, the order picker proves to be extremely maneuverable and ideal for narrow aisles, even with full loads of up to 2,000 kilograms. The powerful acceleration to up to 12 km/h allows fast but at the same time safe goods handling with high handling performance. Power steering and automatic speed adjustment ensure maximum safety when transporting both pallets. The low-entry access, the intuitively operated and ergonomic steering wheel, and the spacious operator's platform promote healthy working conditions.

-

CONVENIENT ORDER PICKING WITH FREE LIFT

The picker N20 C L simplifies the picking process with a single pallet in multiple ways: Without load the vehicle accelerates up to 12 km/h. In curves, speed is automatically reduced to protect drivers, goods and pedestrians. Thanks to the 2.2 kW lift motor, the driver can bring the pallet to a height that is easy on the back and load it with up to 1.2 tons. Since the vehicle is easily accessible from both sides and has a pedestrian function on both sides, the operator saves unnecessary travel. Non-slip handles and easy-to-understand operation also ensure higher handling performance. For orders on the first and second shelf levels, the N20 C L can be optionally equipped with a lifting platform. A non-slip floor mat provides firm footing at any height.

-

BACK-FRIENDLY PICKING OF TWO PALLETS SUCCESSIVELY

The N20 C LoL order picker enables the ergonomic filling of two pallets in just one order picking cycle thanks to long load arms and the additional liftable fork. The driver first starts with one pallet at the desired height, while a second pallet is optionally secured vertically to the back of the fork with a special safety device. As soon as the first pallet is filled, it is lowered onto the load arms and transported in front of the fork. The second pallet can then be effortlessly transferred onto the forks and loaded at a height that is easy on the back. The N20 C LoL thus offers fast and ergonomic order picking. In the process, the mast can be controlled to the right and left of the backrest and the vehicle can be moved to the next rack segment. As an option, the operator's platform can be raised to allow occasional picking on the second rack level. The initial lift also ensures easy transport over ramps and uneven surfaces.

-

SIMULTANEOUS PICKING ON TWO PALLETS AT OPTIMUM OPERATOR HEIGHT

With its scissor lift, the N20 C LX order picker is a powerful and ergonomic order picking solution and can lift and transport up to 2,000 kilograms. During order picking, the driver comfortably lifts the forks to the optimum height to avoid unnecessary stress. This means that two Euro pallets can be filled at the same time to protect the back. The operator's platform can also be lifted as an option for occasional order picking on the second level. The construction of the mast and chassis prevents crushing injuries. In addition, the operator's platform offers good all-round visibility and can also be equipped with a panoramic mirror.

-

PICKING AND TRANSPORTING ON TWO LEVELS

The N20 D and N20 D HP double-deck order pickers enable the simultaneous loading and transport of two pallets. Thanks to the ergonomic lift, the operator can also pick heavy goods at a height that is easy on the back. The two separate levels allow heavy and pressure-sensitive goods to be stowed and transported. The N20 D HP high-performance version is also optimally balanced with ground contact via five points and guarantees maximum stability even at speeds of up to 12 km/h. The operator platform is fully suspended on all forklift trucks and therefore reduces vibrations while driving.

-

ERGONOMIC PICKING ON TWO PALLETS

Equipped with long load arms and an additional liftable fork, the N20 LoL from Linde Material Handling enables the loading of two pallets at a back-friendly height in just one order picking cycle: First, the driver fills one pallet at an ergonomic height and attaches the second pallet vertically to the back of the fork. As soon as the first pallet is fully loaded, the driver lowers it onto the load arms and transports it in front of the fork. The operator then effortlessly transfers the second pallet onto the forks and starts the next job at a height that is also easy on the back. The position of the operator platform in front of the battery allows the operator to observe their surroundings while driving and to react to dangerous situations at an early stage. Thanks to the fully spring-loaded operator platform, the operator is optimally protected against shocks and vibrations during the journey. A robust steel bumper at the front of the order picker ensures improved protection of the forklift truck frame and operator platform.

-

EFFICIENT AND SAFE ORDER PICKING FOR A WIDE RANGE OF REQUIREMENTS

The N20 B, N20 - 25 and N20 - 25 HP low-lift order pickers from Linde Material Handling enable a highly efficient and safe order picking process thanks to their unique truck architecture with the battery located between the operator platform and forks: With a maximum fork length of 2,400 mm, various types of loads up to 2,500 kilograms can be transported. The position of the operator platform ensures an optimum view of the warehouse environment during the journey. Using the 3 kW three-phase AC motor, the order pickers can accelerate up to 14 km/h, depending on the truck type, to enable fast transport even over long distances. The intuitive Linde steering wheel allows the driver to maneuver forwards and backwards with ease. The small turning circle facilitates maneuvering in narrow aisles. The fully spring-loaded operator platform compensates for vibrations and shocks, and ensures a low-load picking cycle.

-

Versatile load transport in all areas of operation

The autonomous Linde P-MATIC electric tow tractor with operator platform is designed for load transfers in work areas with restricted space. It can move towing loads of between 3000 and 5000 kilograms. Typical uses in warehouses and industrial businesses include the delivery of production materials, disposal of waste products, and hauling of larger loads. The tow tractors, whether as individual vehicles or part of an autonomous fleet, thereby form an integral link in the supply chain – from production to the delivery area. The versatile and robust vehicles have powerful, maintenance-free drive motors with high torque. -

QUICK AND SAFE TRANSPORT PROCESSES IN NARROW AISLES

The P20 electric tow tractor and the W04 platform truck feature a particularly slender design. Direct, responsive steering makes tight turns possible. As a result, these tow tractors are perfect for transport processes in narrow aisles and tight spaces. Ergonomic working conditions are ensured, for example thanks to the height-adjustable seat. The seat also folds up and down. This allows the driver to control the tow tractor from either a standing or seated position. The P20 and W04 can pull a maximum load of two tons. There is also a different version of the W04 model available with a platform that has a load capacity of up to 400 kilograms.

-

TRANSPORT HEAVY LOADS SAFELY AND QUICKLY

The P250 electric tow tractor from Linde Material Handling transports very heavy loads over medium and long distances quickly and safely. Amongst other things, this is made possible by powerful electric motors and smooth hydraulic steering, which makes the tow tractor easy to maneuver. The turning radius of the P250 is also very small. Hydraulic oscillating elements are positioned between the cab and the chassis. This construction prevents unevenness in the driving surface leading to powerful shocks in the cab. The solid, one-piece chassis surrounds the whole truck. It is particularly rigid and is specially constructed for the tough demands encountered in heavy-duty operation. The P250 electric tow tractor tows a maximum towing capacity of 25 tons and reaches a top speed of 25 kilometers per hour.

-

MANEUVER AND TRANSPORT MATERIALS IN NARROW AISLES SAFELY AND WITH AGILITY

Linde Material Handling's P30 electric tow tractor and platform truck are perfect for flexible and safe transport over short and medium distances; even (and especially) when there is very little space available. The truck features precise self-centering power steering that the driver safely controls using the ergonomic two-handled steering unit. In addition, the P30's compact design makes maneuvering narrow aisles easier. The powerful three-phase motor accelerates quickly to its maximum speed. For comfort and stability while driving, the trucks are equipped with an adjustable backrest and a full-suspension standing platform with a nonslip floor covering. The P30 has a maximum load capacity of three tons. It can reach a maximum speed of 10 kilometers per hour.

-

TRANSPORTS LOADS EFFICIENTLY AND QUICKLY THROUGH NARROW AISLES

Linde Material Handling's P30 C and P50 C electric tow tractors allow for efficient and fatigue-free work while transporting goods with load trains. The driver can also benefit from a new platform configuration: the control panel, adjustable backrest and driver standing platform form a u-shaped unit that is completely cushioned, improving comfort while driving. In addition, the electric 2-handled steering unit makes it easier to maneuver when space is limited. The powerful high-torque drive motor ensures high-performance handling. The P30 - P50 C electric tow tractors can pull a maximum load capacity of three (P30) and five (P50) tons.

-

EASY AND EFFICIENT TRANSPORT OF GOODS OVER SHORT DISTANCES

Linde Material Handling's P50 pedestrian tow tractor is designed especially for flexible transport with one or more tow hitches. Users benefit from the easy control, precise acceleration and effective braking that these trucks provide. In addition, the truck is very agile and easy to maneuver in narrow aisles or elevators where there is limited space. The tow tractors are designed to provide stability on three wheels, which allows operators to use the tow tractors on ramps or on uneven surfaces. Its maximum towing load is five tons. It can reach a maximum speed of 6 kilometers per hour.

-

HIGH THROUGHPUTS, EVEN IN THE SMALLEST OF SPACES

The P60 - P80 rider-seated tow tractors and W08 platform trucks from Linde Material Handling tow trailers with heavy loads and provide quick, safe and flexible processes. This allows the decoupled and spring-mounted suspension of all three wheels. It ensures quiet and safe travel. At the same time, the truck has high towing force and a small turning circle. Therefore, the throughput remains high even if there is only a small amount of space available in the warehouse. The driver benefits from a work station with lots of leg room, an adjustable driver’s seat and steering wheel, as well as intuitively arranged control elements. The P60 - 80 electric tow tractors and W08 platform trucks have a towing capacity of 6 to 8 tons. The top speed without load is 20 kilometers per hour.