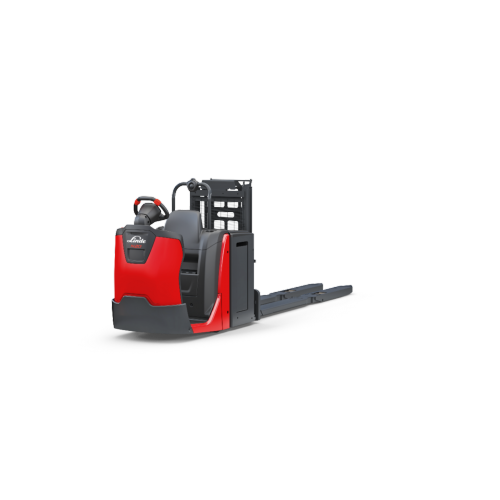

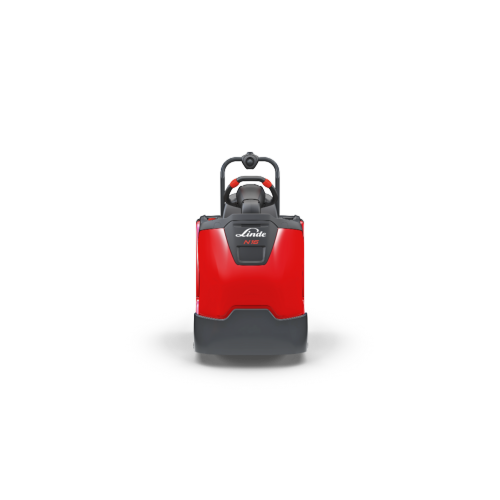

ERGONOMIC PICKING ON TWO PALLETS

Equipped with long load arms and an additional liftable fork, the N20 LoL from Linde Material Handling enables the loading of two pallets at a back-friendly height in just one order picking cycle: First, the driver fills one pallet at an ergonomic height and attaches the second pallet vertically to the back of the fork. As soon as the first pallet is fully loaded, the driver lowers it onto the load arms and transports it in front of the fork. The operator then effortlessly transfers the second pallet onto the forks and starts the next job at a height that is also easy on the back. The position of the operator platform in front of the battery allows the operator to observe their surroundings while driving and to react to dangerous situations at an early stage. Thanks to the fully spring-loaded operator platform, the operator is optimally protected against shocks and vibrations during the journey. A robust steel bumper at the front of the order picker ensures improved protection of the forklift truck frame and operator platform.